Biodegradable Semi-automatic

Tank Cleaning System

Benefit

Time

- Fast Cleaning

- Fast Response Team

Cost

- Quick Asset Use

- Minimize Waste

- Possible Oil Recovery

HSE

- Safe Working Procedure

- Environment Friendly

- Compliance Equipment and Technology

Quality

- Tank Result

- Equipments and Crew Experience and Capability

Time

- Fast Cleaning

- Fast Response Team

Cost

- Quick Asset Use

- Minimize Waste

- Possible Oil Recovery

HSE

- Safe Working Procedure

- Environment Friendly

- Compliance Equipment and Technology

Quality

- Tank Result

- Equipments and Crew Experience and Capability

1| Survey

The objective of site survey:

To assess plot plan area

To ensure completed dimension of tank (manhole, drain line,flange or valve)

To calculate the amount of waste

To fulfill Health,

Safety & Environment (HSE)

requirement needed

Infrared thermal imaging scan is provided before Waste Recovery program in order to ensure sludge recovery and analyze potential problems.

Thermal Imaging

We offer infrared imaging scan, to estimate and calculate remining content in the tank, potential sign for repair plan , hot spot.

Determine how many sludge on the tank for auditable sludge volume.

Infrared Thermography is a non-destructive test that uses an infrared camera to measure radiant heat pattern emitted from mechanical & electrical equipments. The difference in temperature from its normal surrounding will determine the region of possible defects such as leak, crack, material defects, etc.

Vessel or pipes that contain liquid or gas with higher or lower temperature than ambient or room temperature are subject of this infrared test. Defective area in pipe insulation such as: insulation material defects, missing insulation and water trap inside insulation will emit radiant heat or cool thermal pattern that is different from the normal area surrounding it.

Benefit :

Figuring out sludge profile inside

the storage tank by analyzing

differences in temperature

Helping individual to know the boundary between sludge and other liquid in the tank

Measuring the height of the sludge

Calculating estimate volume

of sludge in storage tank

2| Close Loop System

The objective of site survey:

Pumping out contained liquid phase from the tank

Pneumatic pumping system to carry out liquid sludge from tank

Vacuum truck unit for discharge sludge / pump to IBC / drums

Free of sludge spill to environment

Minimizing sludge volume

3| Desludging

System

It is a process to dispense oil sludge. Using environmentally friendly chemical to pump out sludge using pneumatic pump. Taking out hard sludge with mechanical and chemical method.

Immediate Pick Up by B3 Transporter

Store in Temporary Waste (Storage Jumbo Bag, ISO Tank or IBC Tank)

Transfer to existing Facilities (Sludge Pond, Tank, etc)

Sludge Oil Recovery (SOR) is a process to separate solid and liquid with the provision of oil specifications with BS & W <= 3%, oil content <= 500 ppm and solid sludge <= 17%.

The result of SOR are:

Crude oil will be returned to production facility

Waste water will be returned to production facility

Solid waste will be packed using drums or jumbo bags

4| Segregation

System

The action or state of setting someone or something apart from others.

Collecting and pumping sludge to IBC Tank for liquid and solid to UN Drum or Jumbo Bag. Segregate between sedimentation, water and condensate.

5| Decontamination

The neutralization or removal of dangerous substances, radioactivity, or germs from an area, object, or person. Using environmental friendly chemical water jetting and or fire pump applicable for cleaning. Drying the tank using blower and rags

Decontamination Sludge’s process:

![[M]Process Decomentation(1)](https://cic-es.co.id/wp-content/uploads/2024/06/MProcess-Decomentation1.png)

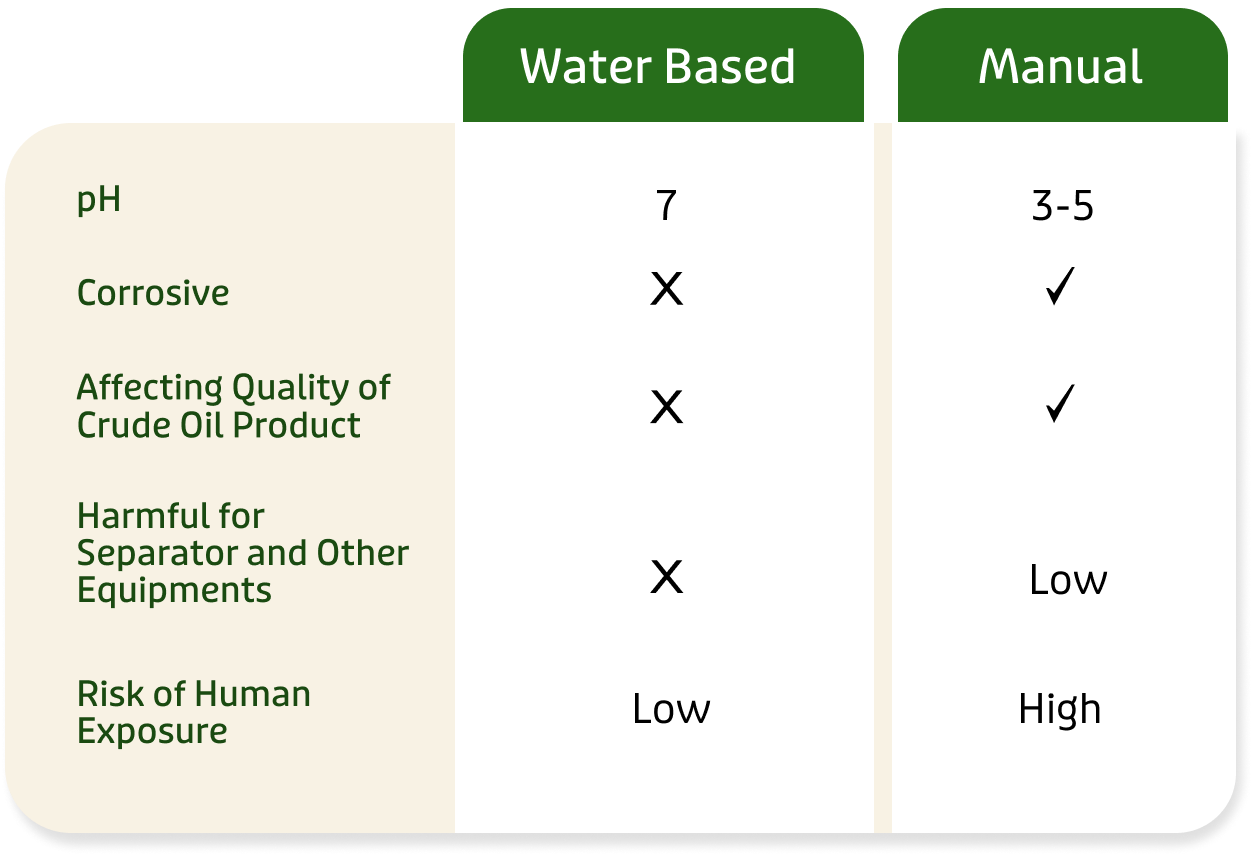

Comparison Table

Water Base and Solvent Base Decontamination Cleaning Agents

Comparison Table

Comparison CIC Biodegradable Semi-automatic Tank Cleaning System VS Manual Tank Cleaning

Our Journey