Equipment Cleaning

The fastest and most efficient method to clean cooling system machines which contain crust, sediment, rust, moss, mud and silica.

Benefit

Biodegradable

Eco Friendly

Non-Food Compounds

Harmless to Skin

Harmless to tools

Fast Cleaning Time

Super Corrosion Inhibitor

Easy to be Applied & Efficient

No warming up needed

No neutralizer needed

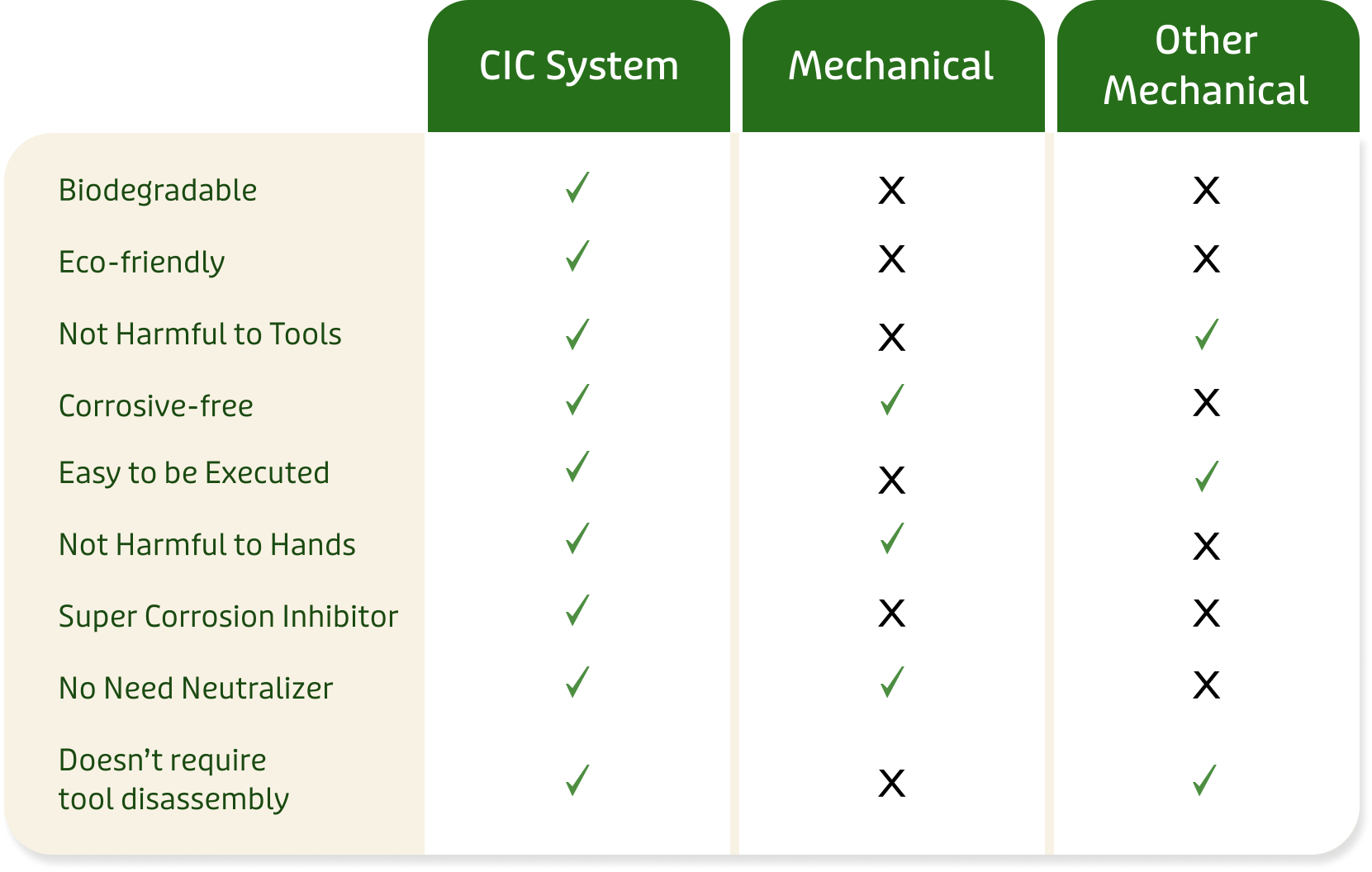

Benefit Comparison

Comparison between CIC System, Mechanical and Other Chemical

Safely Implemented on

Steel

Titanium

Copper

Nickel

Bronze

Brass

Iron

Rubber

Teflon

Plastic

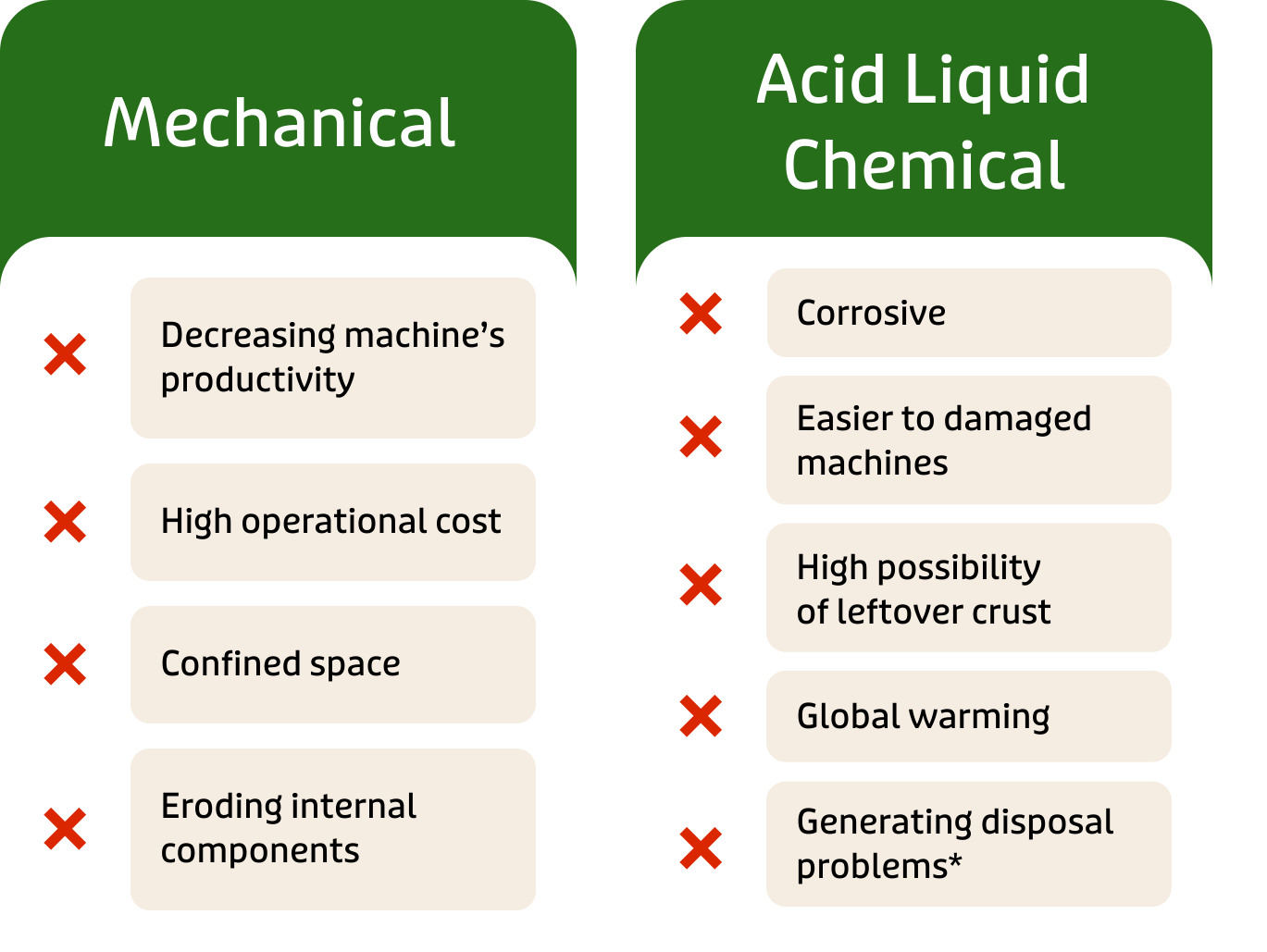

Disadvantages of

Conventional Method

In Cleaning Cooling System

*Violating Government Regulation of The Republic of Indonesia on

Implementation of Environmental Protection and Management article 104

Cooling System

On Oil Refinery

Machine

Plate Heat Exchanger (PHE)

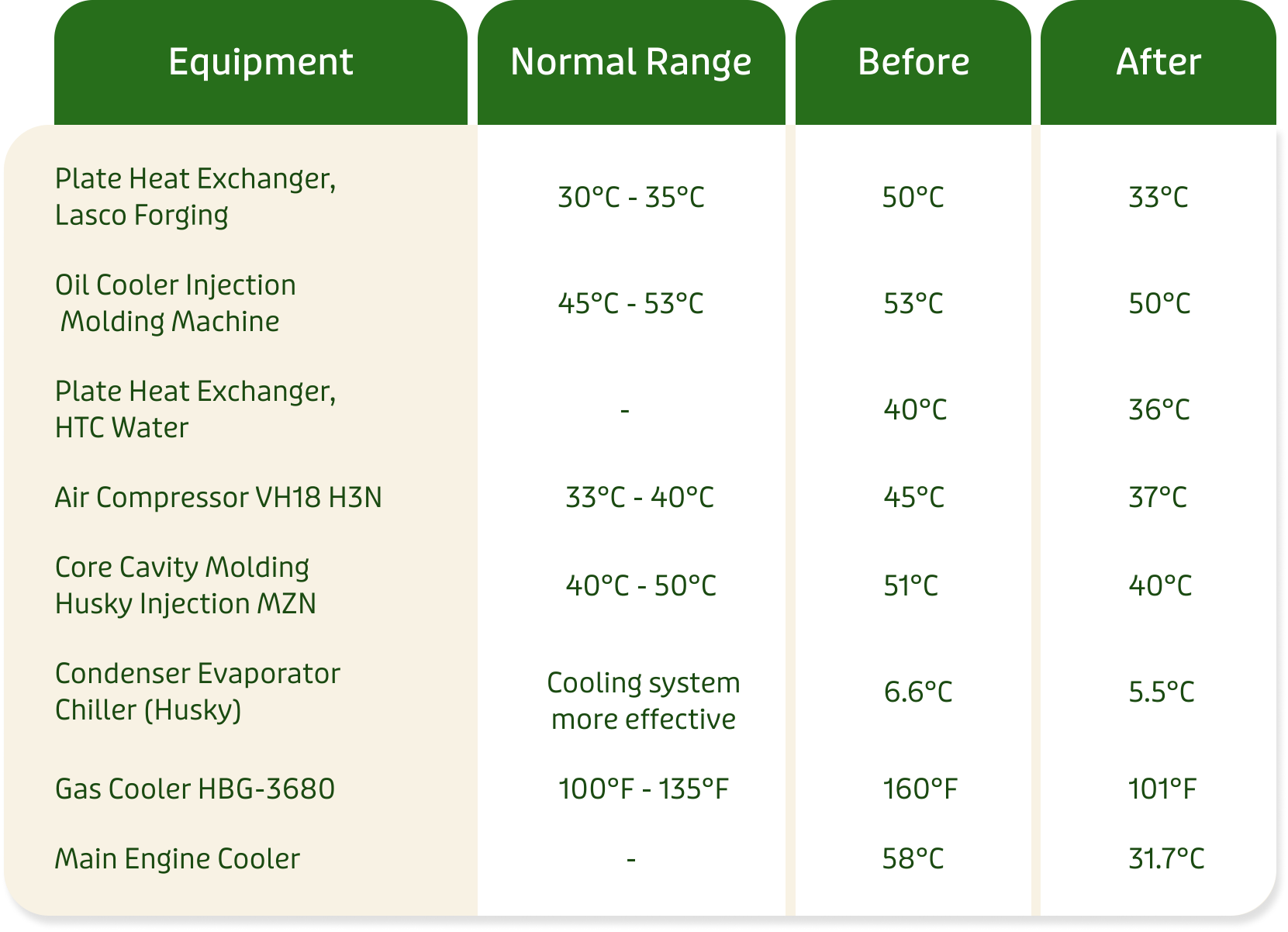

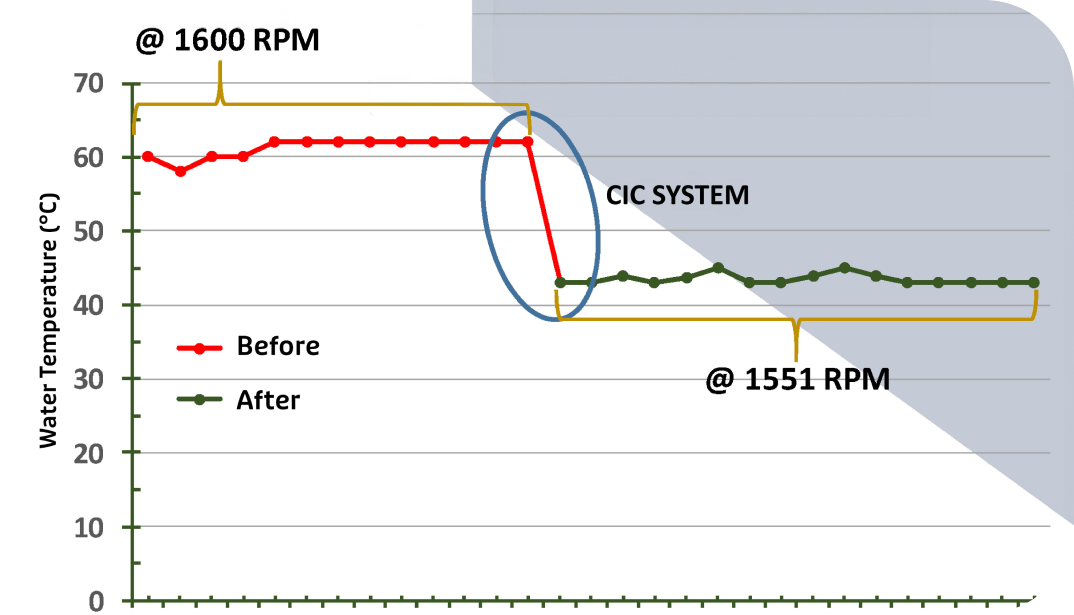

Result Of Cooling

System Machine’s

Performance

Comparison Table of

Plate Heat Exchanger

Cleaning Method

Comparison between CIC System and Manual

· Size of plate heat exchanger (L x W x H) = 70 cm x 60 cm x 150 cm

· Duration of cleaning for manual method refers to KAO Philippine

Application

1| Refinery

(Oil & Gas)

· Exchangers

· Compressors

· Converters

· Crackers

· Pumps Piping

2| Pharmaceutical

· Exchangers

· Loop Systems

· Kathabars

· Pumps

· Reactors

· Stills

· Sterilizers

· Chiller

3| Beverages

· Exchangers

· Heaters

· Rinse Tanks

· Sterilizers & Washers

· Compressor

· Cooling Tower

4| Metals

· Bearings

· Conveyors

· Fans

· Shelters

· Sprays

· Furnaces

5| Automotive

· Closed Circuit

· Cooling

· Extruders

· Dynamometers

· Molders

· Welders

6| Manufacturing

· Exchanger

· Chillers

· Compressors

· Furnaces

· Quenchers

· Vacuum Pumps

7| Other

· Banbury Mixers

· Calendar & Mill Rolls

· Molds

· Injection Molders

· Throat Coolers

· Towers and Tubers

· Temperature Control Units

Project

1| Gas cooler

Implemented at Star Energy Kakap

Result

Cost Benefit Analysis – Income Loss Due to Shutdown

Production / day : 42 mmscfd

Gas price : $6 per mmbtu (approximately)

Conversion rate : 1 mmbtu = 0.00096 mmacf

Income loss per day

42 mmscf * $6 per mmbtu * (1 mmbtu / 0.00096 mmscf) = $262,500

2| Genset Radiator

Implemented at Pertamina Aset 3 Tambun

Result

3| Plate Heat Exchanger

Implemented

at Komatsu Undercarriage Indonesia

Result

Improving production quality of brittle-free link resulting in less rejection rate.

Cost Saving Analysis – Extreme increasement in productivity of plate heat exchanger from 5% to 90%

4| Desalination Unit

Result

Implemented at PJB Indramayu

Cost Saving Analysis

Assuming production cost per hour : $50,000

5| Main Engine Cooler

Implemented at KRI Mentawai 959 – Kolinlamil